Looms of one type or another have been used for centuries to make cloth. They come in all sorts of shapes and sizes and can be used to make simple edgings or braids or can be computerized to create complex designs. As early as 2000 BC, backstrap and horizontal looms were used in the Andes. Native Americans also used a similar “Pacific” loom. The warp threads were tied to a post and held in place by a backstrap. The threads were spaced apart by a single hand-operated heddle.

The warp-weighted loom was used until the Middle Ages. It was comprised of a frame, with a roller beam on top. The warp, (vertical threads of the loom), went through the heddles, (loops of string). The warp threads were held under tension by attaching weights at the bottom of the loom. The heddles raised or lowered the warp threads to make a shed or space so that the weft (the horizontal threads) could be woven across. As each weft thread was woven, it was beaten down into place with a comb, piece of bone or wooden sword.

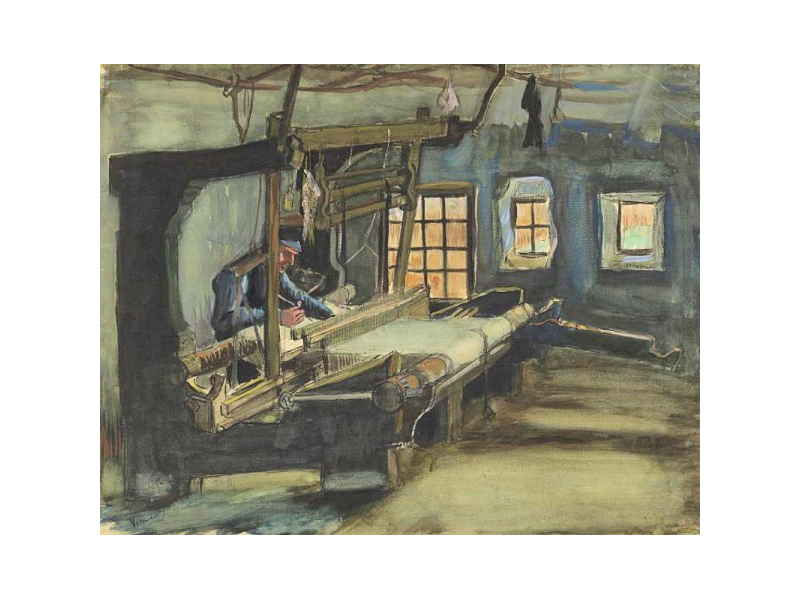

Looms today still work under the same principles. The warp threads are attached to the front and back beams, and are held under tension. Each warp thread passes through a heddle which can be a knotted string, a texsolv heddle or a metal heddle, that raises or lowers the thread, allowing the weft to be woven through the warp threads. Each heddle rests on a shaft or harness.

With tapestry looms, the threads are manipulated by hand. The weft is finger woven through the warp and the design is created through the use of various colours of thread. Some tapestry looms have 2 shafts that are attached to foot pedals. When the pedal is depressed, the shafts are raised allowing the weft to be passed through more easily. Looms can also have multiple shafts, that allow for more complex pattern designs.

Floor looms of today can be classed into 3 types:

Jack Loom

Counterbalance Loom

Countermarce Loom

With a Jack loom, the sheds are raised up when a pedal is depressed. Jack looms can be a bit noisy to operate, as when your foot is removed from the pedal, the shed falls back into place with a bang.

A Counterbalance loom operates on the principle of counterweighting. When some shafts are lowered, the others are raised. This results in a smoother, and quieter weaving action.

The countermarche loom is most popular in Scandinavia and Europe and in my opinion gives the best shed. Due to the pulley action, the warp threads are pulled both up and down, resulting in less stress upon each individual thread. In hand or foot powered looms, the treadling sequence is done from memory. This can result in treadling errors.

To aid in complex treadling sequences, the dobby loom was invented where the raising of the pattern shafts is controlled by a peg system. This system was further enhanced with a computerized version.

More about Looms

Computers and Looms

Did you know that computers and looms have something in common?

How to Warp a Loom

A beginner’s guide to warping a loom, in 10 easy steps.

Cardboard Box Loom

Make your own loom using a cardboard box.

Rigid Heddle Weaving Books

The Weaver’s Idea Book: Creative Cloth on a Rigid Heddle Loom

Handwoven Home: Weaving Techniques, Tips, and Projects for the Rigid-Heddle Loom

Color & Texture for the Rigid Heddle Loom: A Study in Yarn Selection for Weavers

Weaving Made Easy Revised and Updated: 17 Projects Using a Rigid-Heddle Loom

WeaveKnitWear: Simply Fabulous Clothing and Accessories for Rigid Heddle (and Other) Weavers

EBAY – Used Weaving Looms

BAND WEAVING

RIGID HEDDLE LOOMS – US

RIGID HEDDLE LOOMS – UK

EBAY Tapestry Looms

USED TAPESTRY LOOMS – UK

USED TAPESTRY LOOMS – US

USED FLOOR LOOMS – UK

LONGTHREAD MEDIA VIDEO

LONGTHREAD MEDIA VIDEO

LONGTHREAD MEDIA SUBSCRIPTIONS

HANDWOVEN MAGAZINE

PIECEWORK MAGAZINE

SPINOFF MAGAZINE

LEARN LONGTHREAD MEDIA

PAIVATAR HANDMADE

LONGTHREAD MEDIA SUBSCRIPTIONS

HANDWOVEN MAGAZINE

PIECEWORK MAGAZINE

SPINOFF MAGAZINE

LEARN LONGTHREAD MEDIA

PAIVATAR HANDMADE

Paivatar on YouTube

Visit my YouTube channel for how-to craft videos.

Paivatar on YouTube

Visit my YouTube channel for how-to craft videos.

Or Please visit my Channel on Rumble for more how-to videos.

https://rumble.com/Paivatar

LIVE STREAMS - Paivatar Studio

KICK

TWITCH MAKERS&CRAFTING

YOUTUBE

Categories: LOOMS, Small Looms